Recently, Prof. Zhangwei Wang and Prof. Min Song from the State Key Laboratory of Powder Metallurgy at Central South University published a research paper titled "Shearing Brittle Intermetallics Enhances Cryogenic Strength and Ductility of Steels" in the international academic journal Science. Dr. Feng Wang and Prof. Miao Song from the Powder Metallurgy Research Institute are co-first authors of the paper, while Prof. Zhangwei Wang, Prof. Min Song, and Prof. Dierk Raabe from the Max Planck Institute for Sustainable Materials in Germany are co-corresponding authors. The first affiliation of this paper is the State Key Laboratory of Powder Metallurgy, Central South University. Prof. Zhangwei Wang initiated the project and designed the concepts for the paper. The entire project was jointly led and completed by Prof. Zhangwei Wang, Prof. Min Song, and Prof. Dierk Raabe.

Fig.1 The front page of the paper

Link:https://www.science.org/doi/full/10.1126/science.ado2919

Precipitates are crucial forcrafting mechanically strong metallic materials.The strengthening effect originates from the resistance to dislocation motion, the linear plasticity-carrying lattice defects in metallic materials.For a long time, this process can proceed either by dispersing coherent particles through which dislocations must pass under higher stress, or by forcing dislocations to bypass impenetrable precipitates viaOrowan looping.Challenging this conventional wisdom,Prof.Zhangwei Wang andProf.MinSong report the dislocation cutting of B2 (ordered body-centered cubic) nanoprecipitates, typically considered nonshearable intermetallics, in a lightweight compositionally complex steel(CCS)during cryogenic tensile loading.This finding opens up a new path toward the development of strong and ductile metallic materials.

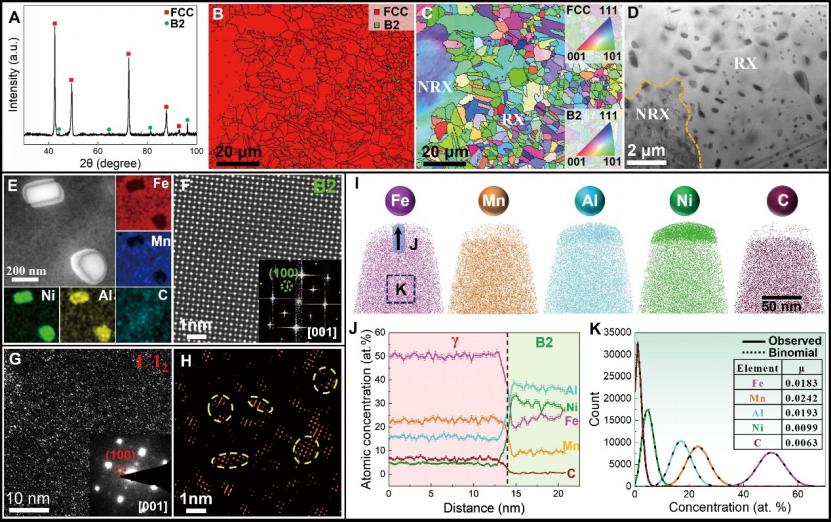

Fig. 2. Microstructures of the hierarchical CCS.

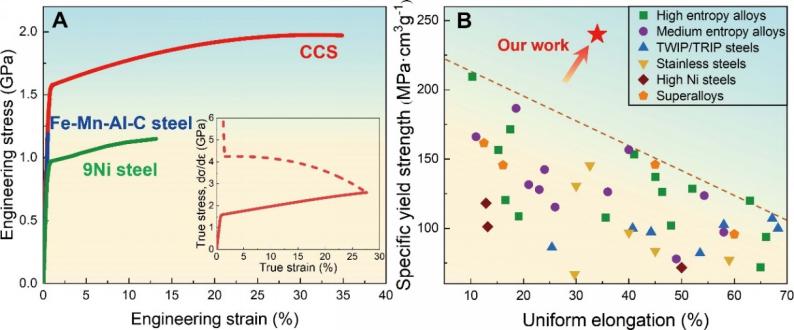

The engineering stress-strain curve under quasi-static uniaxial tensile test exhibitsan ultrahigh yield strength of 1586 MPa and an ultimate tensile strength of 1976 MPa, with a surprisingly high elongation of 34% at near liquid nitrogen temperature.Such remarkable mechanical performanceaddresses the low-temperature brittleness associated with traditional L’12κ-carbide coherent precipitation hardening approaches in austenitic Fe-Mn-Al-C lightweight steels. Thus, combining the benefits of super-highspecific strength and the cost-effective composition, the CCS emerges as a promising alternative for structural materials that can serve in the transportation and storage of liquid gas energy carriers.

Fig. 2. Cryogenic mechanical properties of the CCS.

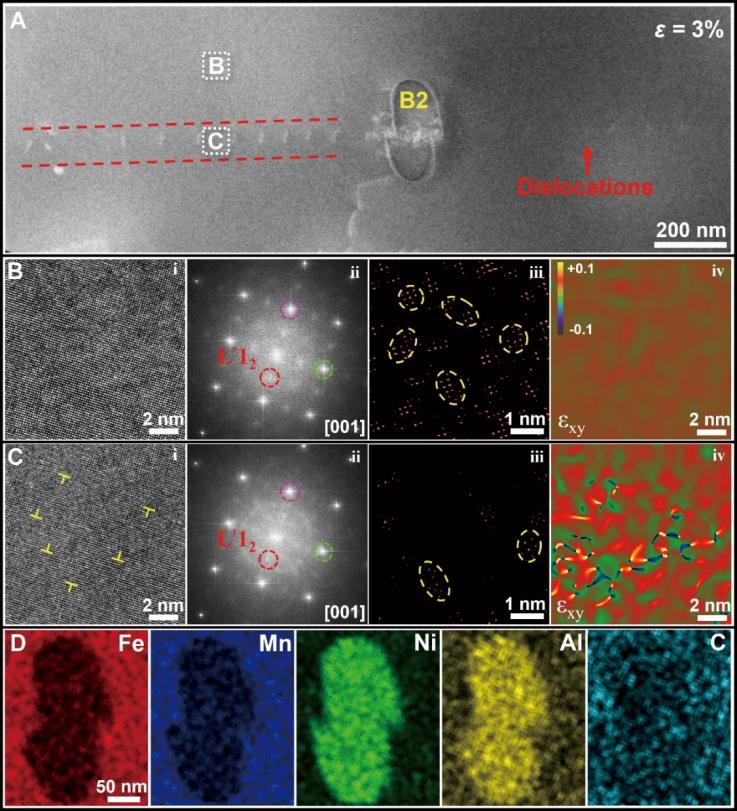

According to research findings, the cut-through of B2 intermetallic particles by planar dislocations during plastic deformation in the CCS arises from an extremely high friction stress at near cryogenic temperatures, caused by the local chemical ordering (LCO) zones and the high solid solution friction stress which both enhance the resistance to dislocation glide in the austenitic matrix. The fraction of sheared B2 particles rises rapidly as the strain increase, since the flow stress increases remarkably due to the additional strain hardening provided by stacking faults and twinning. The sequential cut-through of B2 particles effectively mitigates the stress concentration at the hetero-interfaces between austenite and B2 particles, which further inhibits the potential nucleation of cracks.

Fig. 3. The shear of LCO and B2 particle by dislocation slip.

Fig. 4. Microstructure evolution of the CCS during cryogenic tensile deformation.

Overall, this study designed high-density local chemical ordering structures in austenitic matrix, leveraging the multi–principal element feature of high entropy alloys. Combined with significant solid solution strengthening, the lattice friction stress effectively increased, enabling dislocations to shear the brittle B2 intermetallic compound. This unique mechanism not only harnesses the intense strengthening and strain hardening provided by otherwise impenetrable brittle nanoprecipitates, but also introduces ductility through their sequential shearing with ongoing deformation, significantly enhancing the mechanical properties of the CCS under low temperature conditions.Such surprising approach is expected to be widely applied across various metal materials, further enhancing the performance and meeting the diverse needs of different fields, which would advance the development of metal materials science.

This research represents an important continuation of the previous work by Prof. Zhangwei Wang and Prof. Min Song. In recent years, Prof. Zhangwei Wang has been dedicated to the design and development of lightweight, high-strength steels, uncovering the fundamental strengthening and toughening mechanisms. He has published a series of high-impact papers, including inNature Communications(13 (2022) 3598) andScience Advances(6 (2020) eaba9543). This research achievement has been supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, the Science and Technology Innovation Program of Hunan Province, and the State Key Laboratory of Powder Metallurgy.