(Special materials research team for extreme service environments)

1. Team Introduction

The "Special Extreme Environment Materials Research Team" of Central South University has Academician Huang Boyun as its academic advisor and Changjiang Scholar Distinguished Professor Liu Wensheng as its academic leader. It currently has 11 scientific researchers, including 1 Changjiang Scholar Distinguished Professor, 1 National Zhuoqing, 10 senior professional titles, and 3 provincial and ministerial talents. It has a first-class material design, preparation and test characterization platform in China. In recent years, it has hosted/undertaken more than 30 projects such as major national science and technology projects, national key R&D plans, 173 plan key projects, national defense "973", National Natural Science Foundation key projects, high-level talent funds, etc., with an annual research funding of nearly 20 million yuan. There are 69 full-time graduate students, including 32 doctoral students and 37 master students. Graduates mainly go to domestic and foreign research institutes and well-known enterprises such as the University of Kentucky in the United States, the University of Auckland in New Zealand, Tsinghua University, Central South University, China Academy of Engineering Physics, and China Aerospace Science and Technology Corporation.

二、Members

|

Liu Wensheng, "Changjiang Scholar" Distinguished Professor, Doctoral Supervisor Chief Scientist of the "973" Project Director of the National Key Laboratory of Lightweight and High-Strength Structural Materials Director of the Center for Advanced Studies, Central South University Design, preparation and application evaluation of special extreme environment materials |

|

|

Ma Yunzhu, Second-level Professor, Doctoral Supervisor National high-level leading talents Research direction:Metallic Materials and Powder Metallurgy Materials |

Xiao Daihong, Professor, Doctoral Supervisor Research direction:Lightweight and high-strength structural materials |

|

|

Liang Chaoping, Professor, Doctoral Supervisor Hunan Province Outstanding Youth Research direction:Material calculation and simulation |

Liu Jijin, Associate Professor, Master Supervisor Research direction:Ceramic fiber materials |

|

|

Cai Qingshan, Associate Professor, Doctoral Supervisor Hunan Province Outstanding Youth Research direction:Refractory metal materials, advanced powder metallurgy materials and technologies |

Tang Sai, Associate Professor, Doctoral Supervisor Humboldt Scholar Research direction:Multi-scale calculation of material microstructure and mechanical properties |

|

|

Huang Lanping, Associate Professor, Doctoral Supervisor Research direction:Lightweight and high-strength structural materials |

Tang Siwei, Associate Professor, Doctoral Supervisor Research direction:Electronic packaging materials |

|

|

Yao Shuwei, Associate Professor, Master Supervisor Research direction:Ceramic fiber materials |

Huang Yufeng, Assistant Researcher, Master Supervisor Research direction:High-performance refractory powder metallurgy materials and service behavior of materials in extreme environments |

三、Research direction and research system

Research direction:

1.Refractory metal materials

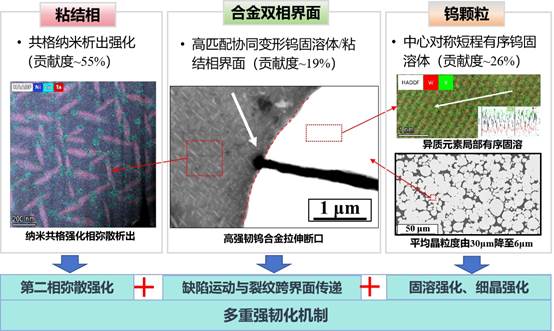

In response to the urgent need for high-performance tungsten alloys in my country's new generation of weapons and equipment, and aiming at core scientific issues such as the organization and mechanical response behavior of tungsten alloys in extreme service environments, we have innovatively broken through the data and space-time limits of multi-scale simulation methods, combined with the residual organization after high-speed impact to achieve a continuous description of the origin-development-transformation of deformation, and obtained the tungsten particle design criteria; subverting the design and preparation ideas of tungsten alloys, innovatively proposed a "short-range ordered structure" design concept based on the central symmetry of electron concentration to improve the intrinsic brittleness of pure tungsten, and used original key technologies such as solid-liquid phase diffusion competition regulation of solute elements to achieve tungsten solid solution edge dislocation-screw dislocation slip deformation and in-situ coherent precipitation strengthening of the bonding phase, and the new high-strength and toughness tungsten alloy developed has greatly improved its strength and toughness. The results have been successfully applied to model scaled parts, and the penetration efficiency has reached the international advanced level.

Figure 1 New high-strength and high-toughness tungsten alloy material

2.High performance aluminum alloy

Focusing on the performance optimization problem of aluminum alloys in service environment, we have been conducting long-term research on the microstructure control and toughening design of high-performance aluminum alloys, proposing the "target performance-oriented" alloy design concept, and building a technical system for the coordinated control of composition-structure-performance. Research directions include: optimization design of aluminum alloy composition based on multi-scale calculation, nano-precipitation phase/interface strengthening mechanism and precise control of microstructure, and environmental adaptability evaluation and engineering application of aluminum alloys. We have undertaken 4 national-level research projects and 2 major horizontal projects, published more than 80 papers in well-known domestic and foreign journals such as Journal of Materials Science & Technology, Materials and Design, Metallurgical and Materials Transactions A, Journal of Alloys and Compounds, Materials Science and Engineering A, and obtained more than 30 authorized national invention patents.

3.Ceramic fiber materials

Focusing on the urgent need for high-performance alumina continuous fiber materials for major national strategic equipment such as hypersonic vehicles and high-thrust/high thrust-to-weight ratio aero-engines, combined with multi-scale material calculation methods, we systematically carry out scientific research on alumina fiber structure design, precursor sol preparation and its spinnable mechanism, fiber structure evolution law and regulation mechanism, and high-temperature service behavior. Based on the grain boundary engineering strategy, by constructing an orderly segregated structure of solute atoms at the grain boundaries, we have broken through the inversion problem between the strength and thermal stability of alumina fibers, and developed a multi-system kilometer-level high-strength and high-thermal stability alumina fiber material, with comprehensive performance reaching the international advanced level. Related results have been published in more than 40 papers in top journals in the ceramic field such as Journal of the European Ceramic Society and Ceramics International, and more than 10 invention patents have been authorized.

picture2 Alumina continuous fiber products and microstructure

4.Electronic packaging materials

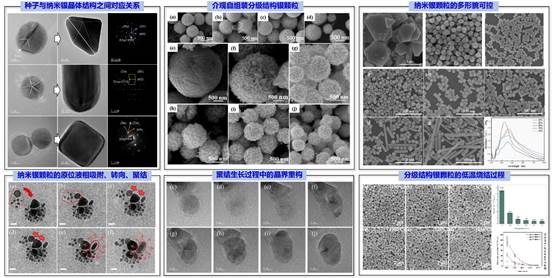

In view of the key requirements of low-temperature packaging and high-temperature service faced by nanosilver particles for packaging of aerospace electronic devices, the molecular dynamics and computational fluid dynamics multi-field coupling simulation method, combined with in-situ analysis and characterization technology, systematically explores the cross-scale regulation mechanism of the silver particle nucleation-growth-self-assembly process by the hybrid dynamics, concentration gradient distribution and surfactant molecular configuration in a chemical reduction environment. The research work covers the evolution of grain boundary reconstruction behavior at the atomic scale, nanodroplet coalescence dynamics to mesoscopic self-assembly morphology, establishes a size focusing model and morphology controllable synthesis strategy based on seed-mediated reaction dynamics, reveals the key scientific laws of high specific surface area self-assembled silver particles in the micro-nanoscale synthesis and sintering process, and realizes the design of multi-morphological self-assembled unit structures such as nanosilver wires/sheets/nets. The research results provide an innovative path for high-reliability electronic interconnect materials from atomic-scale structural optimization to mesoscopic-scale assembly reinforcement, promote the leapfrog development of precision electronic packaging technology towards submicron-level structural regulation and low-temperature high-densification sintering, and strongly support the advanced manufacturing needs of aerospace flexible circuits, new energy vehicle power chips and 5G millimeter wave devices.

picture3 Self-assembly and low-temperature sintering of multi-morphological micro-nano silver powders

5.Material calculation and simulation

We are committed to solving key scientific problems of materials in extreme service environments. We combine first-principles calculations, molecular dynamics simulations, dislocation dynamics, micromechanics and other methods to explore the behavior mechanisms of materials under extreme service conditions such as high and low temperature, high pressure, high electromigration, high strain rate, strong impact, strong corrosion, and strong irradiation. The research work covers nano-micro-meso-macro cross-scale simulations, realizing the spatiotemporal continuity description from the origin of electron atoms, phase structure development, microstructure evolution to material failure response, and focusing on the application of advanced artificial intelligence algorithms AI4S (deep learning, large language models, etc.) in material design, preparation, service, and characterization. The direction revolves around the research and application of materials, and has developed a number of thermodynamics, molecular dynamics, diffusion dynamics, crystallography and deep learning related software to provide support for material performance prediction and design, and to help the development and engineering application of new materials.

picture4 The material origin-development-transformation-completion spatiotemporal continuity model enables accurate description of material behavior under extreme environments

6.Multi-scale calculation of material microstructure and mechanical properties

In view of the complex extreme environments such as high temperature, high pressure, high strain and high salt faced by aerospace metal structural materials during their service process, multi-scale computational methods such as crystal plasticity finite element, phase field simulation, molecular dynamics, phase diagram calculation, etc., combined with deep learning, are used to conduct in-depth research on the multi-scale organizational evolution mechanism of metal structural materials such as high-strength aluminum alloys and tungsten alloys for aerospace in extreme environments, as well as their behaviors such as electrochemical corrosion, mechanical deformation and damage failure.

picture5 Multi-scale simulation of the evolution of microstructure and mechanical properties of metal materials

Representative Publications

1.刘文胜,蔡青山,黄宇峰,先进钨材料及其制备,中南大学出版社, 2023.

2.The bifunctional low mismatch nano strengthening phase leads to a high strengthductility W-Ta-Ni-Fe-Cu alloy, Journal of Materials Science & Technology, 2024, 205: 139-149.

3.Effects of cerium micro-alloying on microstructural evolution and dispersion strengthening in Al-Yb-Er-Zr alloy, Journal of Alloys and Compounds, 2024, 1010: 177229.

4.Effects of Cerium micro-alloying on microstructural evolution and dispersion strengthening in Al-Yb-Er-Zr alloy, Journal of Alloys and Compounds? (2024) 177229.

5.Precipitation behavior and properties of an Al-8.26Zn-1.95Mg-1.89Cu-0.08Sc-0.17Zr alloy with different dislocation morphologies via pre-treatment, Journal of Materials Research and Technology 29 (2024) 4714-4727.

6.Synergy of strength-ductility in a novel Al-Zn-Mg-Cu-Zr-Sc-Hf alloy through optimizing hierarchical microstructures, Journal of Materials Science & Technology. (2024) 105-122.

7.Atomic-scale investigation on the evolution of T1 precipitates in an aged Al-Cu-Li-Mg-Ag alloy, Journal of Materials Science & Technology. 209 (2025) 139-148.

8.The oriented growth behavior of α-Al2O3grains in alumina-mullite biphasic fibers[J]. https://doi.org/10.1016/j.jeurceramsoc.2023.09.016

9.Coordinated regulation for α-Al2O3and mullite structures in the alumina-mullite fiber based on the different adding form of fe element[J]. https://doi.org/10.1016/j.jeurceramsoc.2024.01.043

10.Development and strategy of alumina-mullite diphasic fibers with high thermal stability[J]. https://doi.org/10.1016/j.jeurceramsoc.2024.01.019

11.Optimizing Silver Paste Conductivity with Controlled Convection for Nanowrinkle Growth.ACS Applied Materials &Interfaces. https://pubs.acs.org/doi/10.1021/acsami.4c07047.

12.Container-Free Microfluidic Chemical Reduction for Synthesizing Ultrafine Silver Powder and Fabricating Silver Paste.Journal of Alloys and? Compounds. https://doi.org/10.1016/j.jallcom.2024.177733.

13.Size-controlled synthesis of ultrafine silver powders for electronic paste using a one-pot aqueous method.Materials & Design. https://doi.org/10.1016/j.matdes.2025.113773.

14.Deformation-induced ω phase transition in polycrystalline tungsten under extreme shock loading. https://doi.org/10.1016/j.scriptamat.2024.116432.

15.High-temperature structural stability and mechanical properties of η-carbides M6W6C, M3W3C and M2W2C from first-principles calculations. https://doi.org/10.1016/j.ceramint.2025.02.335.

16.Chemical short-range order synergistically strengthening and toughening Cu-Fe-Ni medium entropy alloys for tungsten-based composites. https://doi.org/10.1016/j.msea.2025.147801.

17.Tetrahedral Lithium Stuffing in Disordered Rocksalt Cathodes for High-Power-Density and Energy-Density Batteries. https://doi.org/10.1021/jacsjacs.4c15631.

18.Heterogeneous phase deformation in a dual-phase tungsten alloy mediated by the tungsten/matrix interface: Insights from compression experiments and crystal plasticity modeling. International Journal of Plasticity, 183, 104156.

19.Phase-field investigation of intergranular corrosion mechanism and kinetics in aluminum alloys. Journal of Materials Research and Technology, 30, 8841-8853.

20. Predicting the in-plane mechanical anisotropy of 7085 aluminum alloys through crystal plasticity simulations and machine learning. Materials Today Communications, 38, 108381.