|

宋旼(Min Song) |

Group leader, Research Fellow (Grade 2), graduated with a PhD from Dartmouth College in the United States in 2005, mainlyengaged inthe mechanical behavior and structural evolution of metal structural materials and metal matrix composites using electron microscopy and computational simulation methods. |

|

王章维(Zhangwei Wang) |

Professor, graduated with a PhD from Dartmouth College in the United States in 2017, mainly engaged in the design, preparation, and the strengthening and toughening study of high-entropy alloys and lightweight high-strength steels. |

|

倪颂(Song Ni) |

Research Fellow, graduated with a PhD from the University of Sydney in Australia in 2012, mainly engaged in electron microscopy analysis of defect evolution in metal structural materials. |

|

欧小琴(Xiaoqin Ou) |

Associate Professor, graduated with a PhD from Delft University of Technology in the Netherlands in 2018, mainly engaged in the study on molecular dynamics simulation of metal structural materials. |

|

顾及(Ji Gu) |

Associate Research Fellow, graduated with a PhD from Central South University in 2019, mainly engaged in the study on plastic deformation and structural evolution of metal structural materials. |

|

何骏阳(Junyang He) |

Associate Research Fellow, graduated with a PhD from University of Science and Technology Beijing in 2017, and holds a postdoctoral position at Max Planck Institute in Germany. His main focus is on the design, characterization, and service behavior analysis of high-entropy alloys and superalloys. |

Research Fields

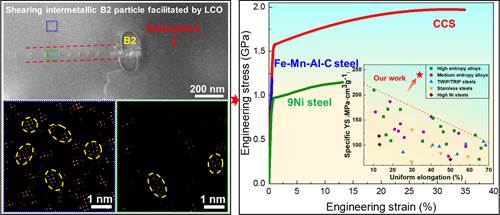

①Structural design, microstructural control, and strengthening and toughening of lightweight high-strength steels

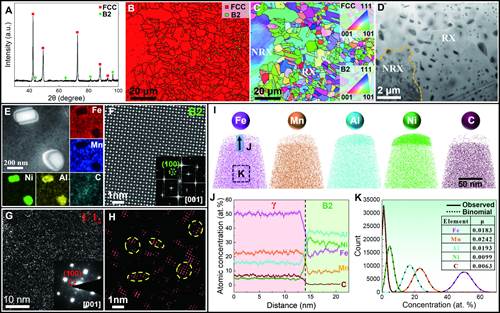

Figure 1: A new deformation mechanism of dislocation shearing intermetallic compounds in Fe-Mn-Al-Ni-C steel.

(From Science, 2024, 384: 1017-1022)

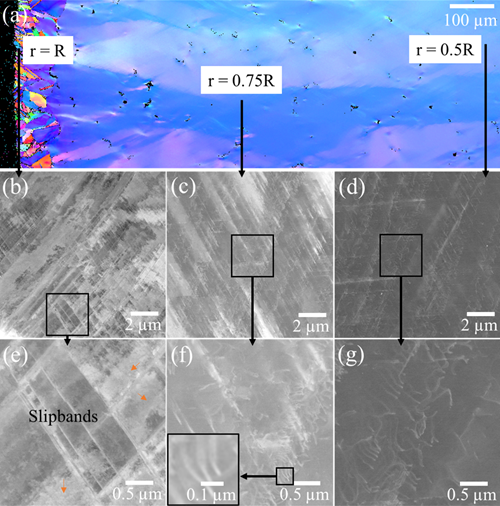

② Composition design, microstructural control, and strengthening and toughening of high/medium entropy alloys

Figure 2: Deformation mechanism of gradient structured NiCoCrMo medium-entropy alloy.

(From International Journal of Plasticity, 2023, 164: 103592)

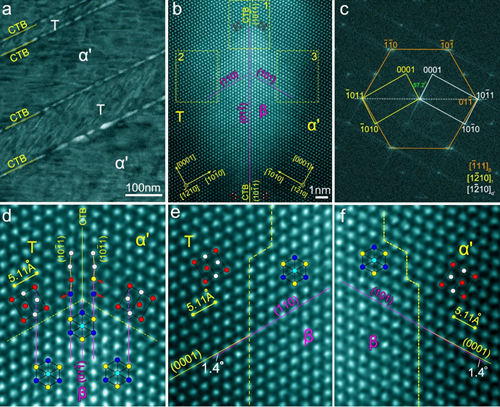

③ Microstructure and deformation mechanism of hexagonal closely packed structured metals

Figure 3: Inhomogeneous precipitation along twin boundaries in Ti-Mo alloy.

(From Acta Materialia, 2023, 242: 118466)

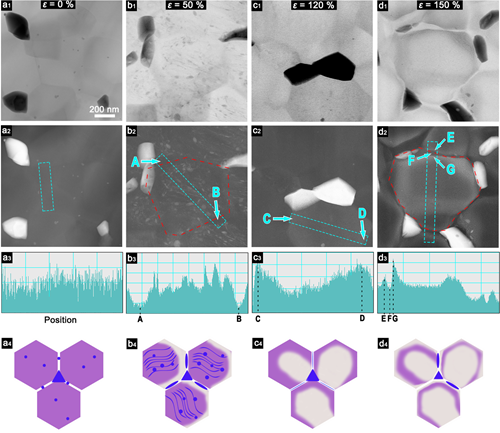

④ Microstructure and deformation mechanisms of cubic structured metals

Figure 4: Structural evolution during room temperature superplasticity deformation of Al-Zn alloy.

(From Acta Materialia, 2023, 246: 118671)

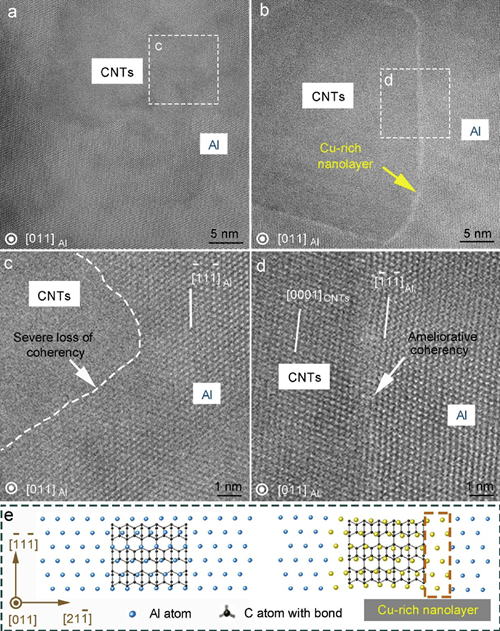

⑤ Preparation and deformation mechanisms of metal matrix composites

Figure 5: Nano Cu particles coated CNTs reinforced Al-based composite material.

(From Carbon, 2020, 159: 201-212)

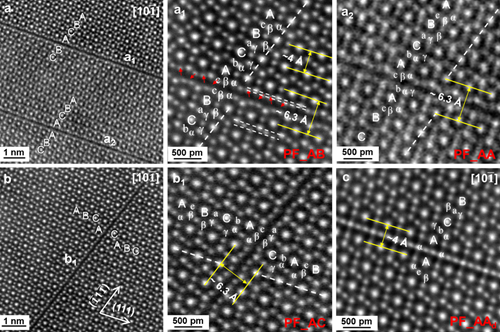

⑥ Advanced characterization techniques: electron microscopy and atom probe tomography

Figure 6: Planar defects in C15 Laves phase of Co-Al-W-Zr superalloy.

(From Acta Materialia, 2024, 264: 119568)

⑦ Computational Materials Science: Machine Learning, Molecular Dynamics Simulation, and First-Principles Calculations

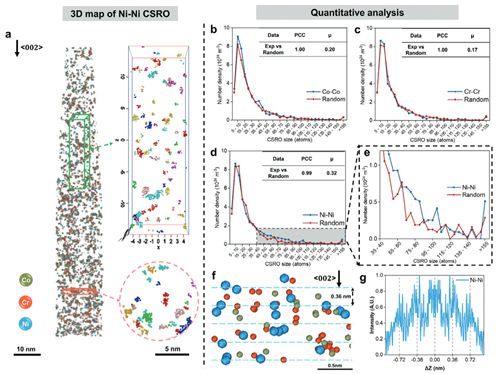

Figure 7: Machine learning enabled APT identification of chemical short-range order in CoCrNi alloy.

(From Advanced Materials, 2024, 2407564)

Research results:

Rewards: First Prize for Technological Invention in Hunan Province, Third Prize for Natural Science in Hunan Province

Patents: 17 authorized patents

Papers: the team has published over 400 papers in journals including: